Kraft Paper Making Line

What Is Kraft Paper?

Kraft paper is a type of brown paper that’s typically made from wood chips. For over a century it has been used for everything from packaging to printing. Kraft paper usually comes in large rolls that can then be cut and shaped for the desired use. Even though kraft paper isn’t waterproof, it’s strong enough to provide a waterproof barrier if treated properly. The most common way to treat kraft paper is by coating it with wax or oil. This allows the kraft paper to stand up against moisture, making it perfect for food packaging, one of the most popular uses for kraft paper (more on those later).

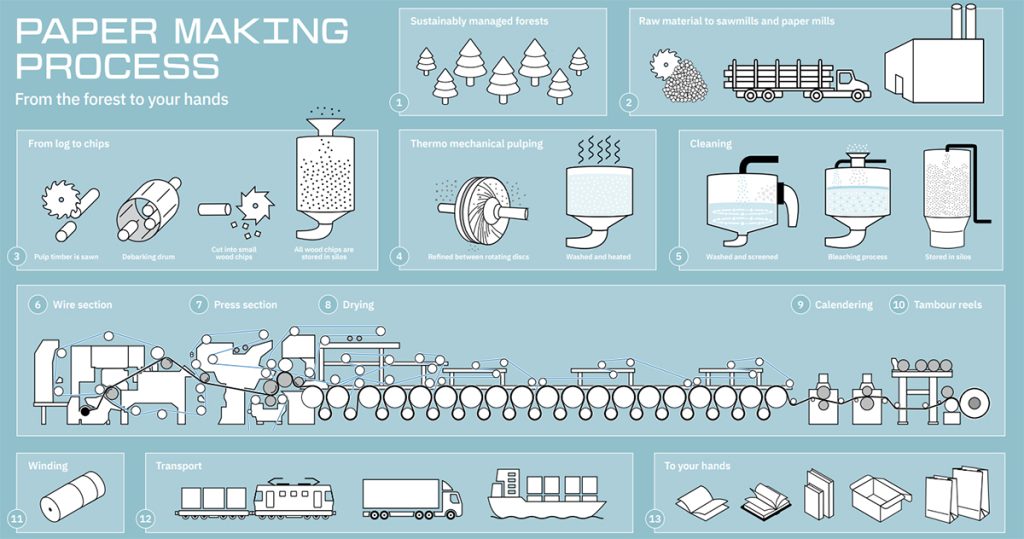

How is kraft paper made?

Kraft paper is made using the chemical process of converting wood into wood pulp. The term “kraft” refers to this process where softwood chips are cooked using intense pressure and heat in a mixture of strong alkaline chemicals. The two structural components of wood are lignin and cellulose. When it comes to making kraft paper, it's the cellulose we need so this needs to be separated from the lignin.

A good way to think about making kraft paper is comparing it to cooking instant noodles. When you first take them out of the packet the noodles are hard and tightly compact together, much like the wood chips. Add hot water to them however and the noodles become soft and separate, this also happens to the properties of the wood chips allowing manufacturers to separate the useful components from the parts that aren’t needed to make kraft paper. The pulp is then washed and screened through large rollers to remove any large chunks and the large rolls of kraft paper that we are used to seeing in factories and manufacturing plants are created. The kraft paper is rolled and dried and is then kept ready to be cut down as required to be made into various items, including brown paper bags.

What machine is used for making Kraft paper?

We can design the production line according to the raw materials type, Production capacity, pulp products and mill-specific requirements. If you are looking for this machine, do not hesitate to contact us or leave your requirements here.